Path to energy storage with net positive impact

Flywheels can decrease the negative environmental impacts of batteries, such as critical raw material depletion. This can be done e.g. by co-location of flywheels and batteries, which extends battery lifetime. This is because flywheels endure frequent charging and discharging better than batteries and can thus buffer the batteries against the need for repetitive cycling.

That makes us curious about the life cycle impacts of flywheels. So far, our analysis indicates that the major impacts of our system come from

- Carbon fibre in the rotor

- Steel in the housing

- Copper in the coils of the motor/generator and active magnetic bearing

That is why these are the materials we put our efforts into transforming while on the way towards large-scale application of our product.

Carbon fibre

Carbon fibre is the major contributor to the carbon footprint of a flywheel due to the need for intense heating during the fibre carbonisation. At the moment, most carbon fibre producers generate this energy from natural gas. We are already evaluating our supplier candidates in terms of actions taken to change this for renewable energy. Also, we are driving towards substitution with recycled carbon fibre as well as looking forward to initiatives like the one by Invest in Norrbotten to capitalise on the renewable energy reserves of Northern Sweden in carbon fibre production.

Steel

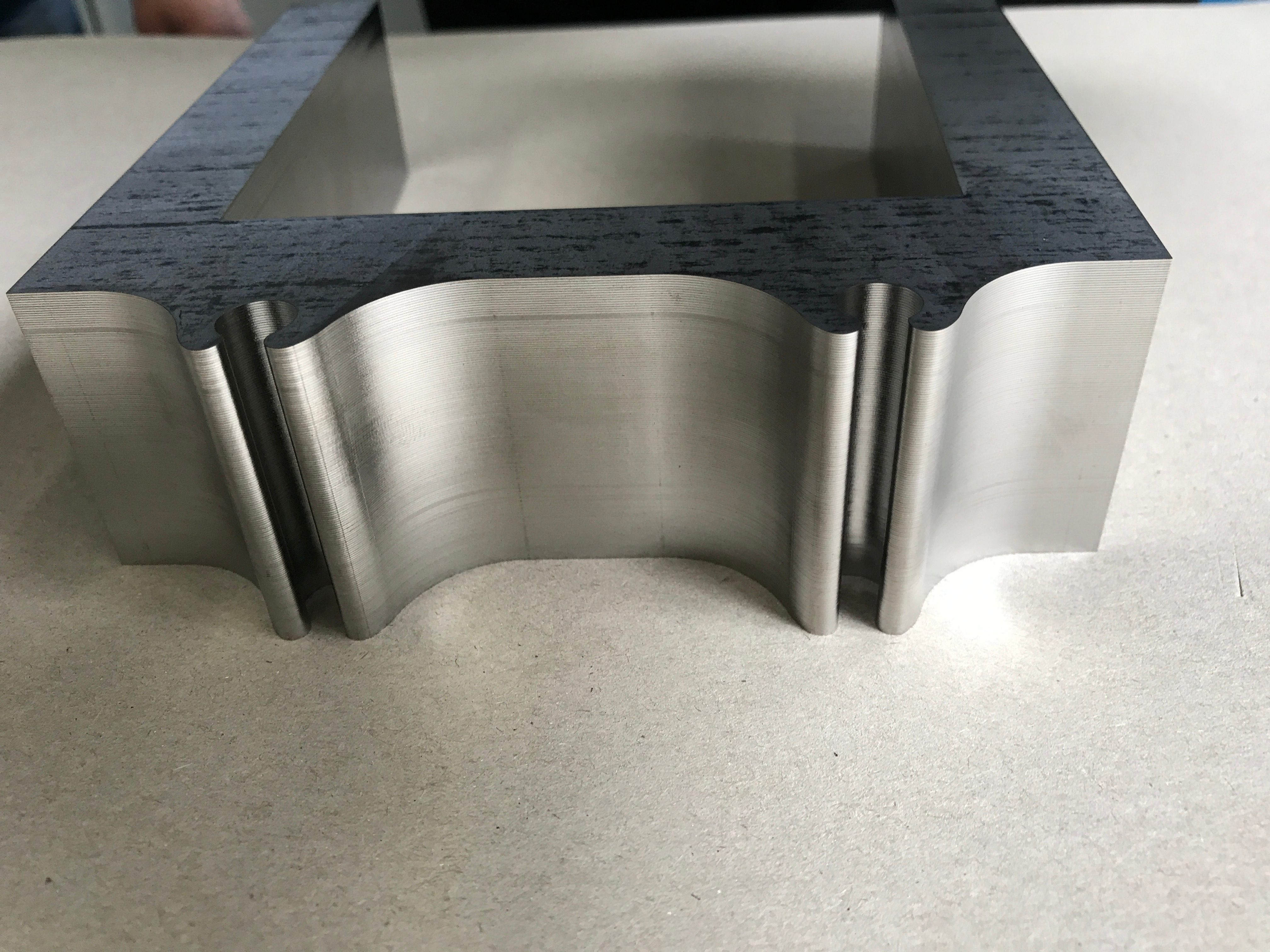

Steel adds mainly to the fine particulate emissions, carbon footprint as well as carcinogenic toxic emissions. Steel is essentially a circular material that can be infinitely recycled, but the expanding stock of steel in growing cities makes the industry dependent on virgin raw materials, as the amount of scrap steel does not satisfy the whole global steel demand. Moreover, steel production is energy intensive, even when using recycled raw materials. [Ellen MacArthur Foundation] We are in search of a supplier for our steel parts who can guarantee maximal use of renewable energy and minimised emissions.

Copper

Copper is the major source for non-carcinogenic toxic emissions among flywheel materials. That is why we are negotiating with suppliers about analysing and minimising these emissions. Furthermore, we are developing superconducting magnet technology that could allow for substitution of most of the copper as well as increase the efficiency of the flywheel.

Overall, compared to batteries, flywheels have a significant advantage of their long lifetime. For example, when estimating the cumulative energy demand per stored MWh of energy in a flywheel and comparing it to a lithium ion battery, a flywheel appears to accumulate less than 10% of the energy demanded by a battery. We are looking forward to studying this in more detail to confirm this estimation. Nevertheless, already this initial study shows that co-locating flywheels with batteries is likely to decrease the impacts of batteries more than it causes its own impacts, thus resulting in a net positive effect.