Our technology

What's under the hood?

Teraloop´s Pillars

All of our solutions are based on three principles to maximize positive effects for our customers and the whole energy value chain.

Durability

In a traditional flywheel, the rotor is physically attached to a central hub. Our system uses a hubless rotor design to minimize the radial stress, thus enabling superior scalability.

Effectiveness

Teraloop Flywheel can deliver energy storage using a minimal area, even 1 MW/m2. Price per kW and OPEX are low, leading to a low total cost of ownership.

Sustainability

Our solution enhances sustainability by improving renewable energy feasibility, reducing the need for critical raw materials through battery life extension, and supporting access to affordable, clean energy.

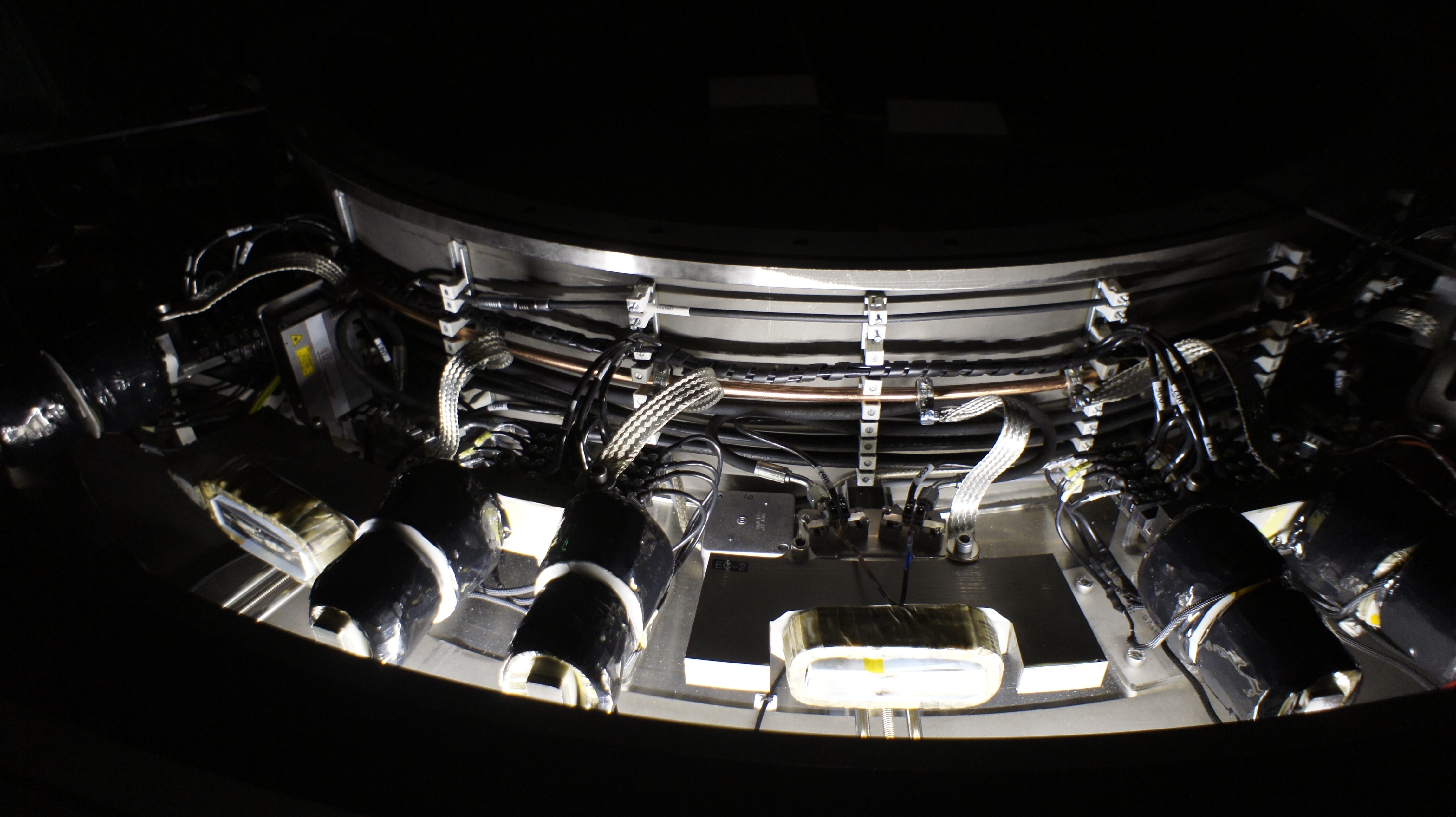

Magnetic Levitation

Technology

We focus on maximizing the "energy per unit mass" of the system, to make efficient use of material resources, while minimizing our site storage footprint.

We utilize combined passive and active magnetic bearing elements in order to provide nearly frictionless contact free operation for maximum efficiency and to allow minimal mainenance over the lifetime of the system.

Motor / generator

Technology

Permanent Magnet Synchronous motor/generator technology is used to maximize both power-density and round-trip efficiency, while minimizing the size of ancillary equipment.

We aim to utilize recycled permanent magnets in order to eliminate our dependency on rare-earth elements.

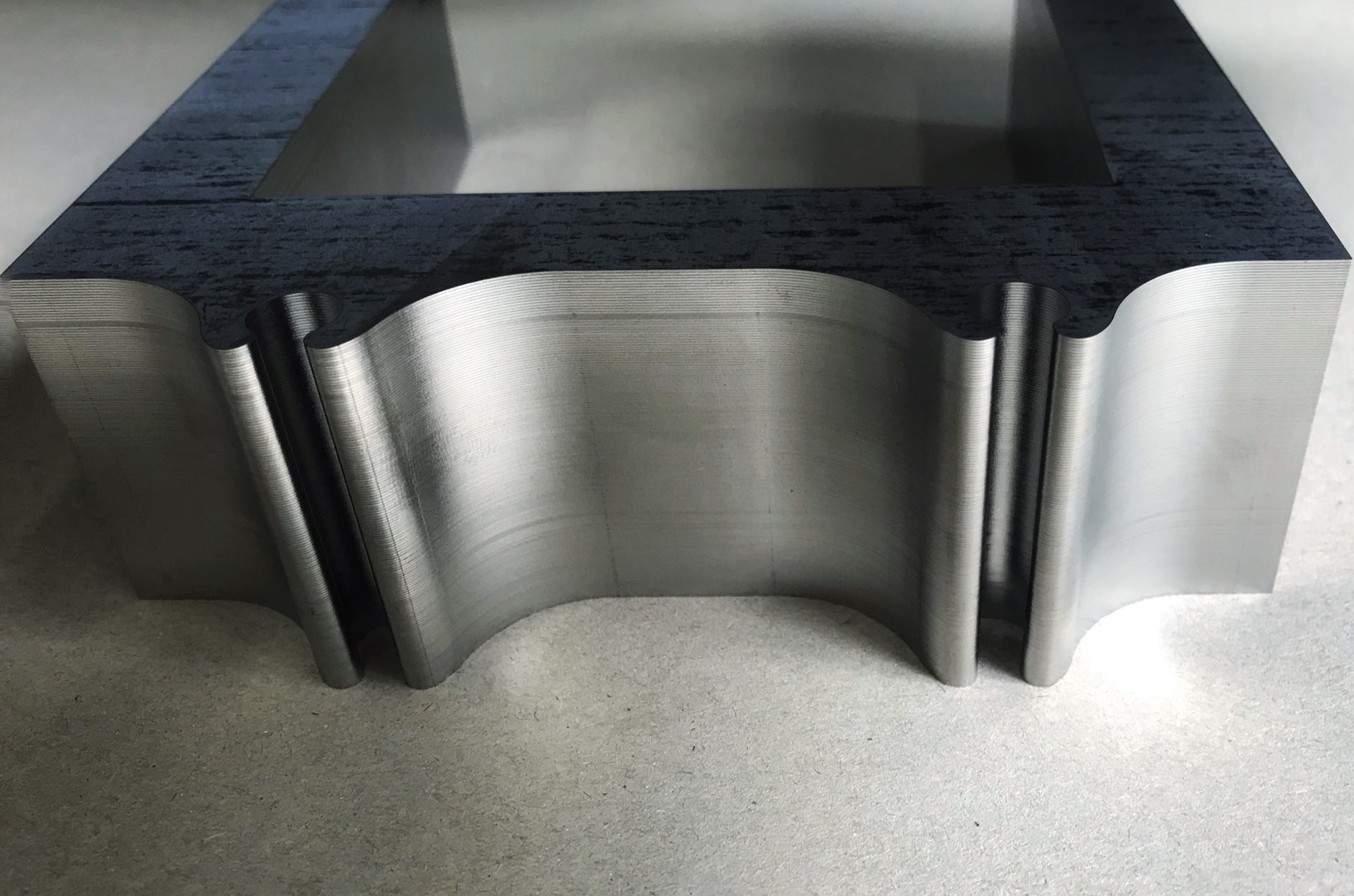

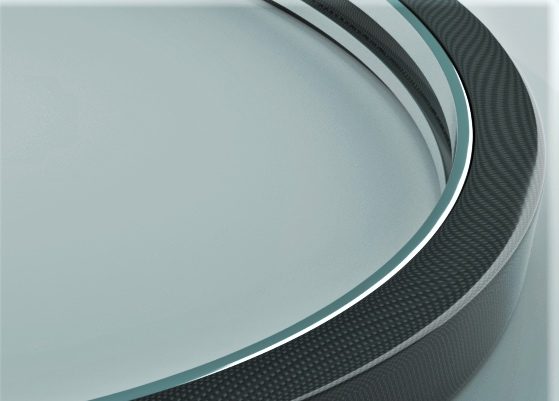

Rotor

Technology

Teraloop's rotor is hub-less, which allows for up to 5 times higher energy storage capacity compared to a rotor with a central hub.

To maximize both storage capacity and sustainability, the rotor is made of light-weight, strong and recyclable carbon fiber composite as well as a mechanically durable magnetic composite.

Materials

We continuously research and develop more efficient, durable and ecologic materials to provide the best solutions both for our customers and the Planet.

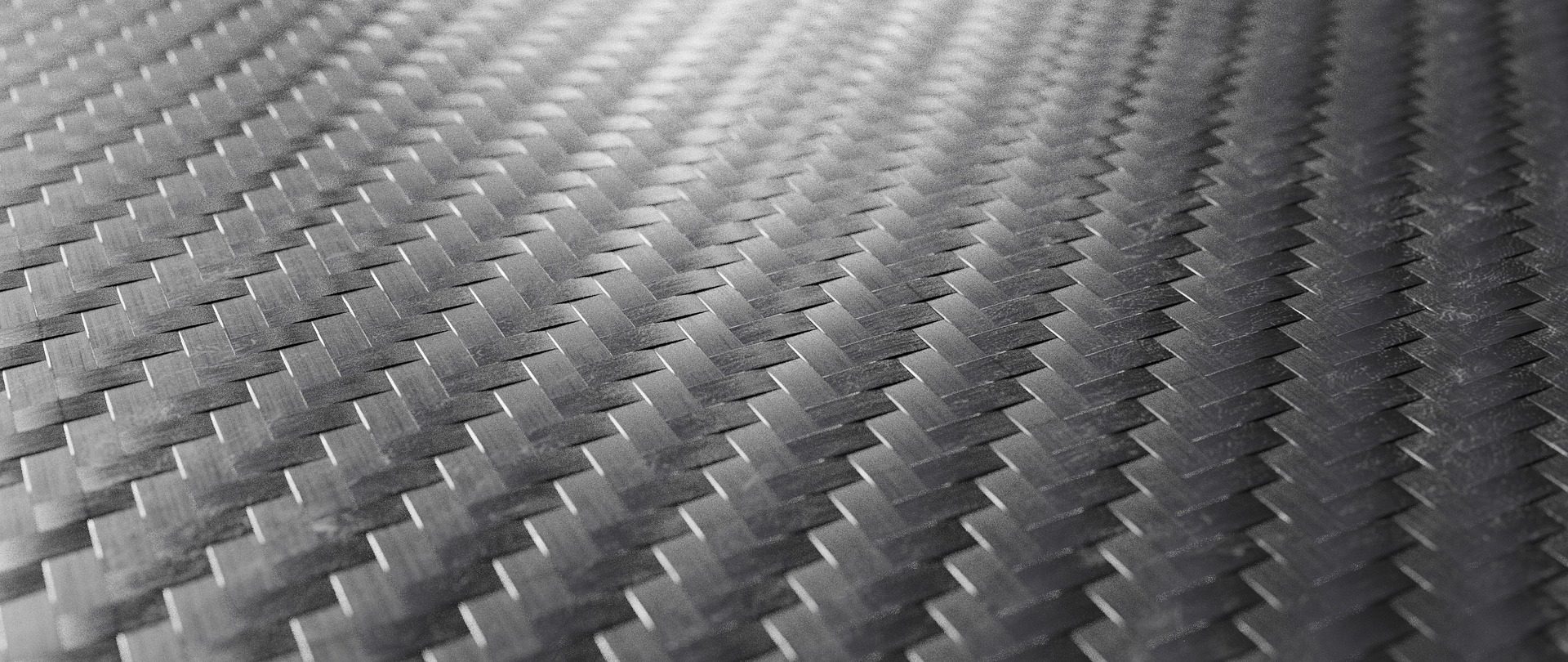

Carbon fiber

Materials

Our flywheel rotor is made of extremely strong carbon fiber reinforced composite to maximize the rotational speed and energy storage capacity of the rotor. We are currently exploring more sustainable and cost-efficient alternatives to traditional carbon fiber, preferably sourced from bio-based or recycled raw materials. In particular, we expect to see a decrease in the cost and carbon footprint of carbon fiber production by manufacturing it from bio-based residues, such as agricultural waste. Furthermore, we aim to contribute to mitigating the accumulation of composite waste by using carbon fiber recycled from other products, such as discarded wind turbines.

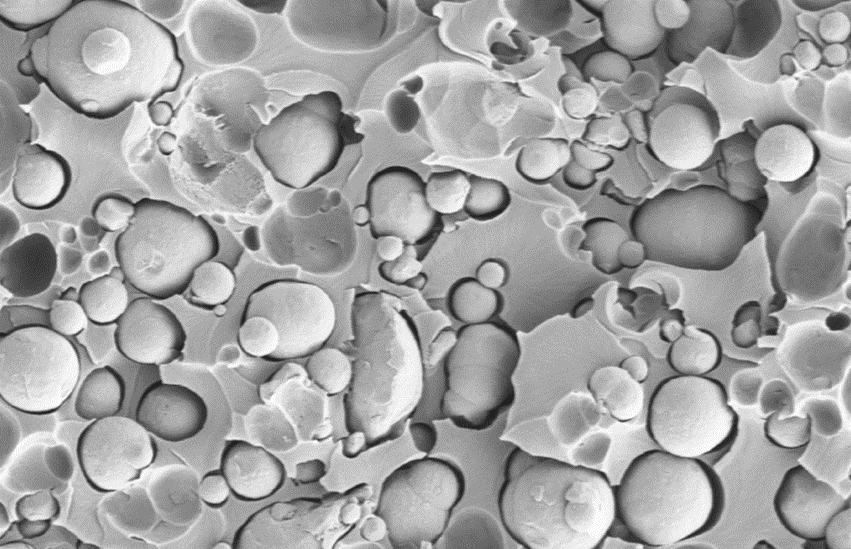

Magnetically loaded composites

Materials

The high rotational speed of the rotor imposes strict demands for the material properties of the magnetic composite used in the electromagnetic stabilization system of the flywheel. In order to further increase the rotational speed and thus the energy storage capacity of the flywheel, we have to improve mechanical robustness and fatigue resistance of the composite while maintaining sufficient magnetic performance. We are currently tackling these challenges as a part of the international SoftCompEl-consortium, founded to develop next generation high-performance magnetic composites. We will achieve these goals with careful selection of resins and magnetic particles, and by controlling their interfacial interactions via suitable surface modification.

We aim to more than double the current specific energy of the rotor to 100 Wh/kg, surpassing current flywheel and supercapacitor technologies. These advances will allow our flywheels to replace Li-Ion batteries for selected applications and reduce dependency on critical materials such as lithium and cobalt.

Epoxy resins

Materials

The sustainability of the rotor is largely determined by the properties of the epoxy resin, where the carbon fiber and magnetic particles are embedded. To reduce the environmental footprint of our products, we aim to transition to epoxy resins that feature reversible curing mechanisms to facilitate reprocessing or recycling of the rotor materials. We are also investigating resins that are based on renewable, non-food chain biomaterials. Both these approaches can decrease the use of petroleum-based and toxic substances, and reduce the greenhouse gas emissions.

The Essence of Teraloop

Discover more on how the hub less rotor works

and why Teraloop´s flywheel is different from other energy storage solutions.