Our fundamentals

The electrical-kinetic-electrical energy conversion system and storage is one of the most efficient energy storage methods available.

By integrating well proven technologies of electric motor drive, magnetic bearings and composite materials we can provide an affordable energy storage solution that has three great advantages:

- unlimited charge/discharge cycles

- no performance degradation over time

- made of abundant materials

Energy is stored in a kinetic form by accelerating a rotating mass of Carbon Fibre Composite to a high speed, using electric motor technology. Once the nominal rotational speed of the rotor is reached, the kinetic energy storage is fully charged.

When energy is discharged, the electric motor is operated as a generator and the rotor speed decreases as the energy is fed out.

The basic principle of kinetic energy of a rotating body can be expressed as Ek=½Iω2.

In this formula, Ek represents the kinetic energy stored in the rotor, I stands for the rotor moment of inertia and ω expresses the rotor angular velocity.

The angular velocity of the rotor has a square term, meaning that doubling the mass doubles the energy, but doubling the speed quadruples the energy. Teraloop's design approach differs from traditional flywheels because it introduces an innovative hubless rotor geometry which allows to maximise the benefit from the ⍵2.

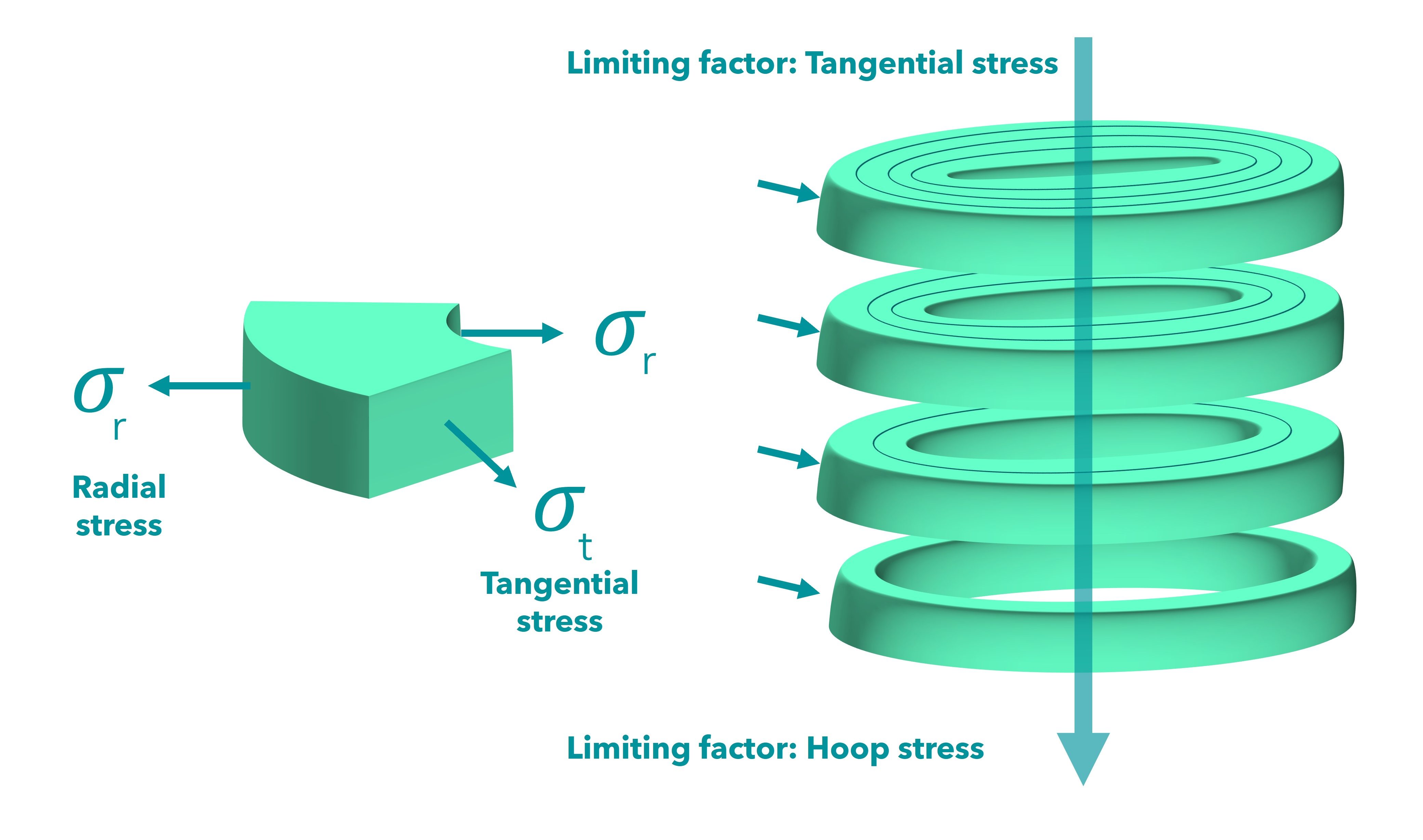

The typical limiting factor for conventional flywheels is radial stress. As the ratio of outer- diameter/inner-diameter approaches equal to 1, the radial stress tends towards zero.

When radial stress is very low, this allows full utilization of the material tensile stress properties, and the majority of carbon fibers can be wound in the circumferential direction. This results in very high specific energy: depending on fiber in use it can be up to 100 Wh/kg.

Teraloop’s hubless rotor design allows five times higher energy storage capacity compared to traditional rotors with a central hub. The hub-less design enables the scaling of the rotor diameter and capacity. To maximize both storage capacity and sustainability, the rotor is made of light-weight, strong and recyclable carbon fiber composite.

A larger rotor diameter results in a larger natural torque arm and higher surface velocity that leads to high power generation. This results in a very power dense motor/generator design which is seen as reduced material use.

For maximised efficiency and maintenance freedom, the rotors are magnetically levitated. Passive and active magnetic bearing technologies are combined to achieve truly contact free operation. By eliminating the bearing friction and introducing a deep vacuum environment the self-discharge rate can be significantly reduced.

The Teraloop energy storage systems feature advanced condition monitoring and automatic shutdown procedure in the rare event of malfunction. The vacuum housing serves as a safety container and ensures environmental safety during the operation. As there are no chemicals used, Teraloop technology can be considered to be a fire safe storage option and allows operation in a wide temperature range.

Teraloop offers a different approach to enable the energy transition, relying on abundant materials like carbon and iron, which are available all over the world. The long lifetime, high reliability, and wide performance range of Teraloop make it complementary with other energy assets.